Your gross margins are hurting.

You’re being bombarded by supplier price increases from all sides. Upsurges in demand have strained the supply of your raw materials, commodities, and components. Delays in trucking and shipping are compromising your deliveries. Finding the right talent amid labor market shortages is driving up labor costs.

All this turmoil translates into inflationary price pressure that many manufacturing businesses haven’t seen in decades.

In a June 2021 survey, the National Association of Manufacturers observed that nearly 87% of respondents reported that the higher prices they were paying were their top business challenge.

For a small business, this profit squeeze is tougher than for big corporations. The latter have more opportunities in their extensive operations or clout in their supply chain to relieve some price pressure.

So, to stay competitive, you have hard decisions to make: Do you spend more to build your inventory? Do you raise prices to pass the costs on to customers? What increases will they tolerate before switching vendors?

What are your options for protecting your profitability?

Consider these three.

1. Work with your supplier to keep prices down

Of course, that’s easier said than done. But by analyzing your sales precisely, you can get a better view of where among your segments of products or customers you can afford to diminish or increase your margins.

For example, let’s say you’re a manufacturing business in the food and beverage industry. Your supplier Jack informs you that the raw materials he provides will increase in price by 3%. If you totally absorb this price increase, your gross margin of $100,000 will drop by $3,000,

Why a precise sales analysis benefits you

Before approaching Jack to negotiate, analyze the product sales that Jack’s raw materials contribute to. Do you see opportunities to segment either the customers or products in order to recuperate that $3,000?

For example, if you’re making less profit on products A and B, is it possible to increase sales and marketing efforts on products C, D, and E, which have bigger margins?

Perhaps Jack can reduce his price for products C, D, and E. Or, Jack can contribute to the marketing of products C, D, and E to help recuperate the lost $3,000. When you work together on a good pricing strategy, a collaborative marketing campaign that’s mutually beneficial could result.

Jack, though, may negotiate aggressively. Remind him that this inflexibility in his pricing will definitely impact the product volume you purchase from him. This possibility should help motivate Jack to find common ground with you.

The key takeaway here is that none of this negotiation would have been possible without a precise sales analysis. The analysis enables you to avoid negotiating on an SKU basis and gives you the leverage to focus on a larger set of products, where you gain more flexibility for the give-and-take of negotiation.

2. Ensure your pricing strategy takes into account all costs

The negotiation described above assumes, of course, that you can accurately assess what Jack’s price increase will do to your own pricing and margins.

In such cases, the accuracy results from the formula you use to set your average price. You may use one of the following two formulas:

- Actual cost. Your formula captures individual costs for transport, customs, foreign exchange, and other elements.

- Supplier cost. In this umbrella category, you’ve included the increase in supplier cost.

When integrating Jack’s cost increase into your average price, you can do one of the following two options:

i) Capitalize it. In other words, include the transport cost in the average cost. Let’s say product A costs $10. Importing a container of product A from China costs $1,000. When product A is entered into inventory, its cost will be $10 plus its portion of the $1,000 transportation charge.

ii) Add transport to the supplier cost. Include the additional cost of transportation in the total supplier cost. At least, the cost increase has been taken into account in your pricing.

Some pricing formulas don’t account for the supplier increase

Many companies, though, simply absorb the hit of the price increase. In such companies, the price is fixed and there’s no mechanism to capture fluctuations in supplier costs.

For example, transport costs may arrive in a separate invoice when product A is entered into inventory. As a result, transportation costs are neither taken into account nor distributed over all of the product A already in inventory.

In fact, when the newly arrived product A is about to be entered into inventory, its price will be set at the same level as the older product A already in the warehouse.

Companies working this way may simply derive their pricing from a static list of costs developed in the past. Furthermore, these businesses can’t get visibility into what components contribute to the increase in overall costs. As a result, the companies don’t know how much to increase prices in order to compensate for lost profitability.

3. Use a pricing strategy that adapts in real-time to costs

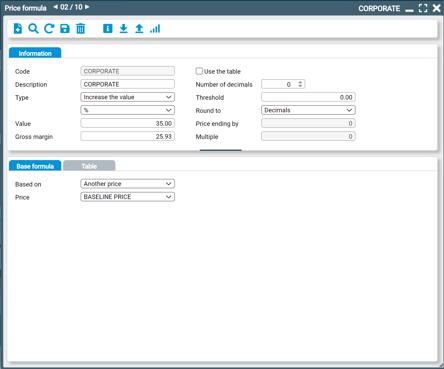

Fortunately, there are software solutions that empower management to get a real-time view of their costs during pricing calculation. The right ERP system, for example, enables you to develop a pricing strategy based on predefined formulas that incorporate real-time costs. So instead of keeping a price list, you’re keeping a list of formulas.

For instance, let’s say your pricing formula is the following: supplier cost + 20%.

The formula making up “supplier cost” includes various elements that you select, such as a benchmark cost, another price, a fixed amount, and so on. (See the screenshot below for an illustration of this pricing dialogue box.)

Thus, if product A costs $10 and you sell it at $12, your gross margin is 16.67%. No matter the supplier cost increase, your selling price always adds 20% to the supplier cost, and your margin remains fixed at 16.67%.

To learn more about how an ERP system can help deal with supply chain turmoil, read our post, “4 Food and Beverage Supply Chain Challenges that ERP Software Can Help You Overcome”

Furthermore, the ERP system’s flexible pricing formulas enable you to add elements for further calculation, such as promotions, discounts, or even multi-level volume pricing. In the latter case, for example, your prices may vary depending on the volume thresholds your customers reach, e.g., 10% off for orders of 100 units, and so on.

Equip yourself to adapt proactively to inflationary pressures

Although this post has focused on how to protect your margins during inflationary times, it’s important to remember that the right ERP system can support and build on your profitability in many different areas of your business.

By empowering you with total visibility into your operations and enabling you to make proactive real-time decisions, the ERP system enhances your overall productivity and agility of response.

If you have more questions, do reach out to us.